Click me to see more Original picture

Click me to see more Original picture

Click me to see more Original picture

Click me to see more Original picture

Film faced plywood can be widely used in various concrete engineering such as high-speed railways, subways, and airport ports, as well as in infrastructure projects such as shear walls, vertical wall panels, bridges, dams and tunnel construction, civil construction and commercial engineering.

Film Faced Plywood Advantages:

-Light Weight

-Easy to Cut

-Reused

-Multi Using

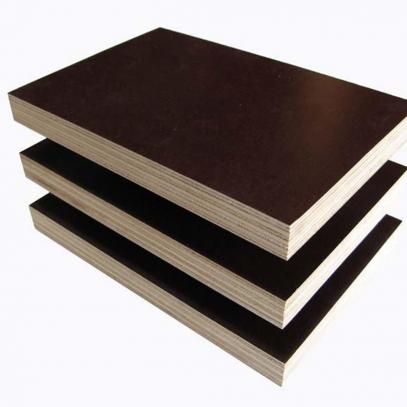

Film Faced Shuttering Plywood Details:

– Product name:Film Faced Shuttering Plywood

– Face/Back: Black Film, Brown Film, Red Film, Anti-slip Film

– Core: Recycle, Poplar, Hardwood, Combi

– Thickness: 9mm to 25mm

– Size: 1220x2440mm,1250x2500mm, as you required

– Density: poplar core 530kg, combi core 550kg, hardwood core 580kg

– Loading Quantity: 8 pallets/23m3/20GP,18 pallets/53m3/40HQ

*Exterior Use

*Stable, Resistant,

*High-Performance Plywood

APPLICATIONS:

| EXTERIOR USE |

| – Outdoor furnishings and fixtures

– Structures, walls, floors – Cladding, home facades, roofing – Joinery, framework, bodywork |

We have full fresh core and recycle core .

One time hot-press/two times hot-press/Three times hot-press

Production Process:

One time hot press:

Planking—2.Molding—3.Pressing

Dealsurface—5.Laminated with hot press

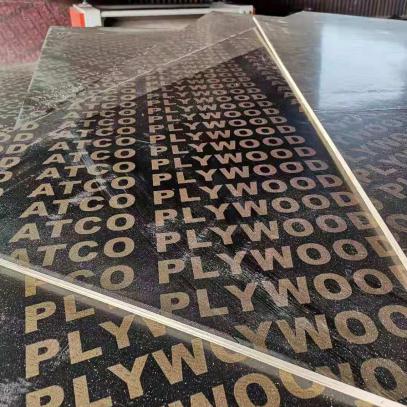

Sawing—7.Checking—8.Printing

Inter package—12.Out package

Two times hot press

1.Planking—2.Molding—3.pressing

4.Hot pressing—5.Dealsurface—6.Sanding

7.Laminated with hot pressing—8.Sawing

9.Checking—10.Printing—11.Inter package—12.Out package

According to the classification:

According the Film color: BrownFilm,Black Film,Red Film etc.

According to the structure: poplar core and finger-joint core

According to the raw material: Poplar core and combi core

According the requirements: One time hot press

Two times hot press

According to the panel: sanding and no sanding

Judge which kind of plywood you need according to your actual situation. All kinds of plywood are produced by booster wood industry with high quality. You are welcome to order.

Product Abstract:Film faced plywood can be widely used in various concrete engineering such as high-speed railways, subways, and airport ports, as well as in infrastructure projects such as shear walls, vertical wall panels, bridges, dams and tunnel construction, civil construction and commercial engineering.

Get a Free Quote