Click me to see more Original picture

Click me to see more Original picture

Click me to see more Original picture

Click me to see more Original picture

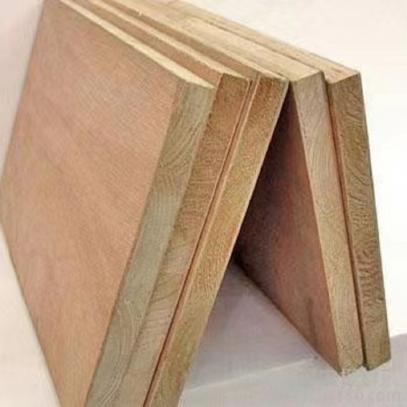

Natural veneer block board and falcate core AAA grade

A block board is a compound wood board made of uniform strips of wood, placed end to end in adjacent columns. They are then sandwiched between two thick veneers of hardwood (usually) and finally glued under a tremendous amount of heat and pressure.

There are several advantages of this amazing product which has made it a reliable and time-tested weapon in the arsenal of designers and manufacturers

Some of the distinct advantages as following:

Lightweight: Block boards are very light in comparison to other engineered wood products that are manufactured using hardwood timber. The lower weight increases the longevity of furniture and doors as they exert less pressure on the hinges. Lightweight further contributes to ease of transport of large block boards or furniture made from it over long distances. Logistical costs are also quite less.

Economical: block boards sourced from quality block board suppliersare going to cost you much less than timber. As a consequence, block boards are the first choice in projects which require cost optimization without compromising on quality.

Resists sagging and warping: block boards have the innate ability to resist sagging or bending. They are stiff and resist bending in the middle, unlike solid timber. This makes it ideal for use in making long bookshelves, tables, benches or wall cabinets.

Resists borer and termite attacks: block boards are treated with special adhesives under extreme heat and pressure conditions which make it highly resistant to biological threats as well as resistant to chemicals.

Uniformly stable and very strong: block boards are formed by placing almost uniform sized blocks of wood end to end in columns, thereby uniformly distributing the strength. Veneers are then pasted across the surface with glue under heat and pressure. This further reinforces the strength.

Poor conductor of heat, sound, and electricity: This property increases the utility of block board and makes it a practical choice for many engineering applications. They are widely used for manufacturing doors, partition boards, switch boards, tables, shelves and wall panels.

Easy to handle: This is a very important property of block board. It is easy to work with and it holds screws and nails quite well. It is dimensionally stable as a result of which it doesn’t bend. Loose grains also don’t come off when drilled.

Easy to reclaim and reuse: block boards are easy to reclaim and reuse in other applications. That makes it one of the most environmentally safe wood products.

Easy to work with under water: block boards are easy to paint, work with and preserve in saline water. Due to its unique structure, it doesn’t become pulpy or brittle under sea water.

Available in many size and thickness categories: block boards are available in many sizes. It is often used in making furniture which is more than 6-7 feet long like wall panels, conference tables, etc. It also comes in many thicknesses. It is light. So it doesn’t pose a challenge in the transportation of huge boards.

Block board could be a very sensible choice for you if you want longevity for your product, convenience in making and a wide range of choices. All this is available at a very reasonable investment.

Judge which kind of plywood you need according to your actual situation. All kinds of plywood are produced by booster wood industry with high quality. You are welcome to order.

Other Products

Radiata PINE PLYWOOD for furniture and decoration

White Birch plywood for furniture and decoration

commercial plywood for packing

Melamine paper faced plywood for cabinet making

CDX pine plywood for roofing and construction and outside use

Okoume or Bintangor faced block board

PENCIL CEDAR PLYWOOD for furniture

okoume face plywood for furniture use

South American teak veneer

Product Abstract:Block board could be a very sensible choice for you if you want longevity for your product, convenience in making and a wide range of choices. All this is available at a very reasonable investment.

Get a Free Quote